If you’ve been following along with this blog miniseries, you know we’ve reached the final step in the Six Steps to Optimizing Your Compressed Air System. Each step so far has built toward this moment—and today we add the last piece of the puzzle.

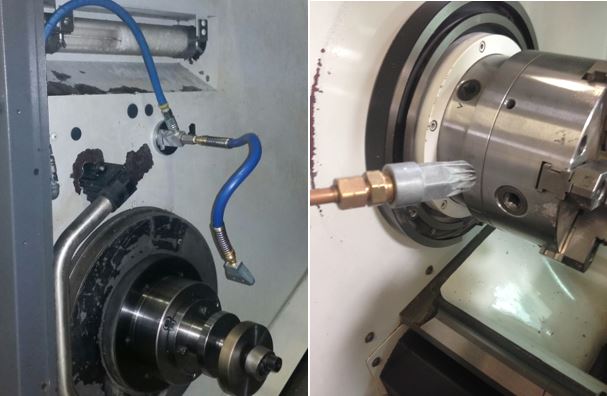

The final step is simple but powerful: control the air pressure at the point of use to minimize consumption.

This is done by installing one of our pressure regulators, available in multiple pipe sizes and flow capacities. A small change in pressure makes a big impact. For example, reducing operating pressure from 100 PSIG to 80 PSIG lowers energy use by nearly 20%. In many cases, operations can run at even lower pressures, unlocking even greater savings.

This reduction in energy use is also coupled with the fact that pressure regulators make any compressed air-operated tool infinitely adjustable. Not all applications require the full output force or RPM, or conveying rate that can be achieved at full line pressure with a compressed air-operated product. And so the humble pressure regulator enables this ability for energy savings and control that is on par with any electrical control for voltage or even frequency. Pressure regulators also facilitate our working mantra to use the least amount of pressure and volume necessary to accommodate the application objectives.

All of our regulators are standard stock items, which means they can ship the same day if ordered by 2:00 P.M. Eastern Time. Plus, with 2D and 3D CAD models available through our CAD Library, you can design your entire compressed air system virtually before making a single cut in pipe.

This step, combined with the previous five, gives you a complete roadmap to compressed air optimization. From measuring usage and fixing leaks, to implementing engineered solutions, automating control, using intermediate storage, and now regulating pressure—EXAIR is here to help make the process straightforward and effective.

As always, if you’d like to discuss your application or explore how we can help you optimize your compressed air system, feel free to reach out.

Brian Farno, MBA – CCASS Application Engineer

BrianFarno@EXAIR.com

@EXAIR_BF